Again, because the company doesn’t maintain a sizable stock inventory, it may be unable to meet the market demand on a timely basis. Most companies create and hold inventory in excess, meaning they create goods in anticipation of other orders. The Just in Time method involves creating, storing, and keeping track of only enough orders to supply the actual demand for the company‘s products.

JIT Inventory Management Software

Here’s how to optimize the post-purchase experience and keep customers happy. CFI is the global institution behind the financial modeling and valuation analyst FMVA® Designation. CFI is on a mission to enable anyone to be a great financial analyst and have a great career path. In order to help you advance your career, CFI has compiled many resources to assist you along the path. Cassie is a former deputy editor who collaborated with teams around the world while living in the beautiful hills of Kentucky. Prior to joining the team at Forbes Advisor, Cassie was a content operations manager and copywriting manager.

Great! The Financial Professional Will Get Back To You Soon.

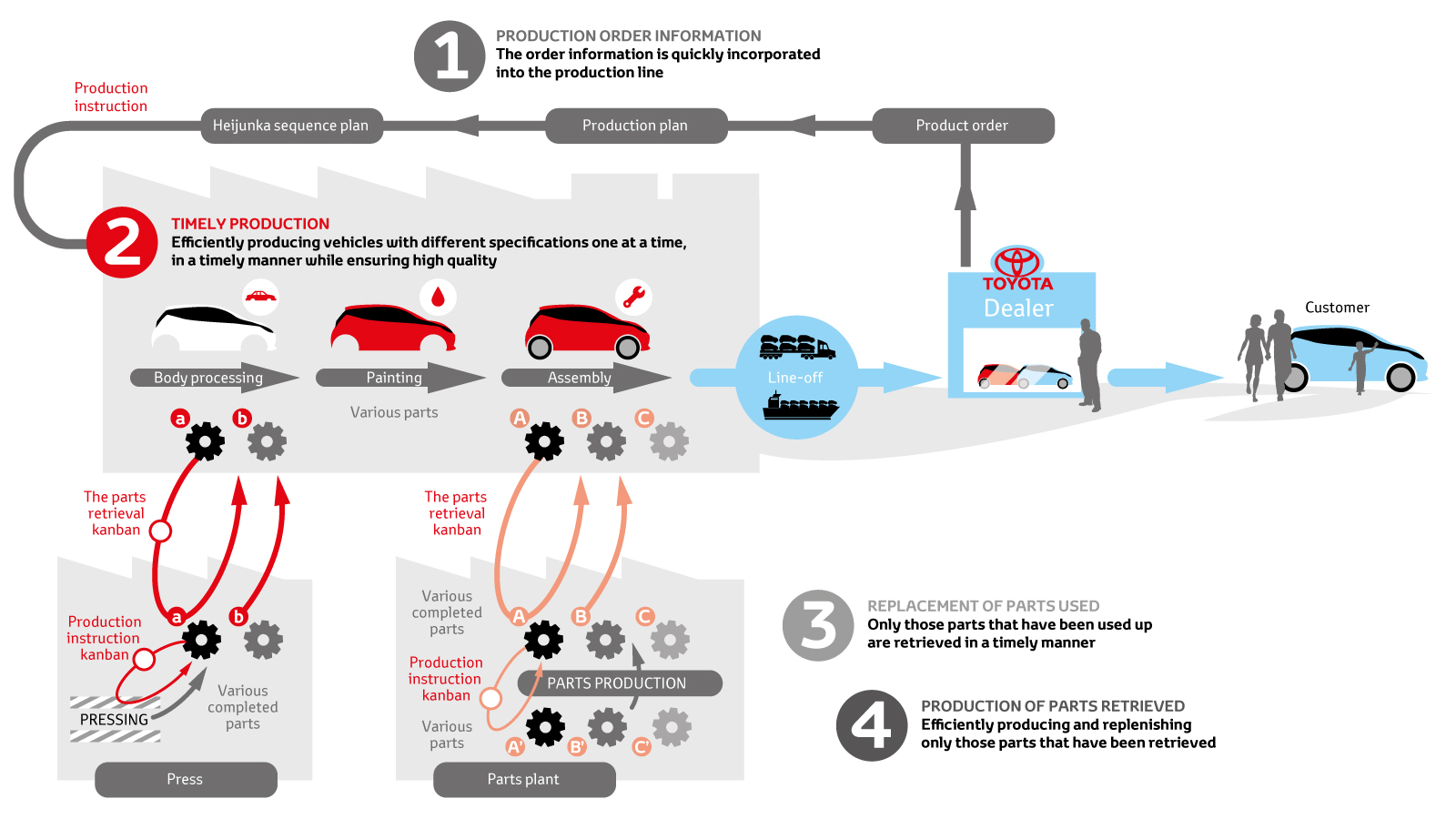

JIT inventory management can be a very effective way to reduce costs and improve efficiency. JIT inventory management works by carefully coordinating the production and delivery of goods. Companies using JIT typically have close relationships with their suppliers, who agree to deliver goods quickly and reliably. All this makes it easier to actually get your replenishment orders when they’re needed and reduce your inventory costs. Let’s say you’re running a manufacturing business, and you’ve currently got so much raw material on hand that it’s taking up space on your shop floor and slowing down the production process. To solve this problem, you might opt to use a JIT inventory management technique, like the Kanban system.

What is just-in-time manufacturing (JIT manufacturing)?

Of course, with a JIT system, you risk running into stockouts if you miscalculate customer demand or run into any disruptions to your supply chain operations. That’s why we recommend JIT solutions primarily to established businesses with strong supply chain relationships and a solid understanding of production times and customer demand. Stockouts can have a drastic impact on customer satisfaction, so businesses using the JIT strategy will need to streamline their production processes and supply chain management. In a JIT system, there’s little to no room for errors like missed shipping windows and slower-than-usual production. After all, if you don’t have enough inventory on hand, won’t that lead to longer wait times and unhappy customers?

What Is Just In Time Inventory (JIT)?

While JIT inventory management can offer significant benefits, there are also some potential drawbacks to consider. One major disadvantage is the increased risk of stockouts and production delays. With JIT inventory systems, manufacturers rely on their suppliers to deliver goods on time and in the exact quantities needed. If a supplier experiences a disruption, it can cause a ripple effect that leads to production delays and stockouts. Just-in-time (JIT) inventory management is a streamlined inventory management philosophy that aims to minimize inventory waste and optimize production efficiency. Just-in-Time (JIT) inventory management is a strategy that minimizes the amount of inventory a business holds.

- Cook’s supply chain improvements reduced the amount of time Apple’s inventory sat on the company’s balance sheet, which went from months to days.

- Once the component is used to complete a finished product, the card is removed and sent back up the production line.

- Lower inventory means a reduced total asset figure on the balance sheet, all else being equal.

- Plus, with fewer items on hand, you lower the risk of overinvesting in product you can’t sell.

PDC ships new bumpers to dealers and works with the Parts Redistribution Center (PRC), where Toyota suppliers send their parts. PRC requested that the manufacturer produce a blue bumper for the 2000 Toyota Camry and then forwarded it to PDC. Built-in quality is also a key principle to the success of JIT and the goal should be to achieve zero defects so that extra materials are not stored for remakes. Join our email list below and for the next 28 days, we will send you exclusive tools, templates and guides unavailable on the website. We developed a short and simple 28-day program designed to develop your ability to implement Lean and Six Sigma methods daily. If you’re not sure whether a JIT system is right for your business (or you don’t think you’re properly set up for it yet), there are a couple of things you can do to prep your company for the JIT method.

Companies B and C must wait for raw materials to be delivered to the producer and for production to manufacture the needed goods. For JIT manufacturing to succeed, companies must have steady production, high-quality workmanship, glitch-free plant machinery, and reliable suppliers. High inventory turnover ratios are considered a good sign of operational efficiency, effective purchasing management, and productive use of advertising and promotional campaigns aimed at generating sales. Even smaller retailers can take advantage of the arizona sales tax relatively high many valley rates mostly stable to streamline the delivery process. For example, a company that markets office furniture but does not manufacture it may order the furniture from the manufacturer only when a customer makes a purchase.

A potential disadvantage is that the producing company rarely has any extra stock on hand to fill unexpected orders, which can create two possible problems. The first is that if a customer needs an order filled immediately, the company is unlikely to be able to provide the needed goods because they don’t keep a large, general inventory supply on hand. Contrary to JIT’s methodology of keeping inventory to a bare minimum, just-in-case (JIC) inventory prioritizes being prepared to fulfill any request at any time, with a very short fulfillment timeframe.

It’s unknown exactly when Japanese manufacturers began adopting JIT manufacturing practices, but it is certain that they were triggered by the economic climate of the post-World War II era. Following the war, Japan lacked the cash to finance big-batch, large inventory production methods used by other developed countries. JIT manufacturing helps organizations control variability in their processes, allowing them to increase productivity while lowering costs. JIT manufacturing is very similar to Lean manufacturing, and the terms are often used synonymously. The potential for increased waste is another disadvantage of JIT inventory management. JIT manufacturers strive to eliminate all forms of waste, but there is always the potential for waste to occur.

Her experience in diverse B2B and B2C industries continue to drive her interest in the SaaS customer journey. Rachaelle holds a BA in Communication Studies from the University of Florida. In this post, we’ll discuss the ins and outs of JIT manufacturing, including its history, the basic concepts included in this methodology, and its potential risks.